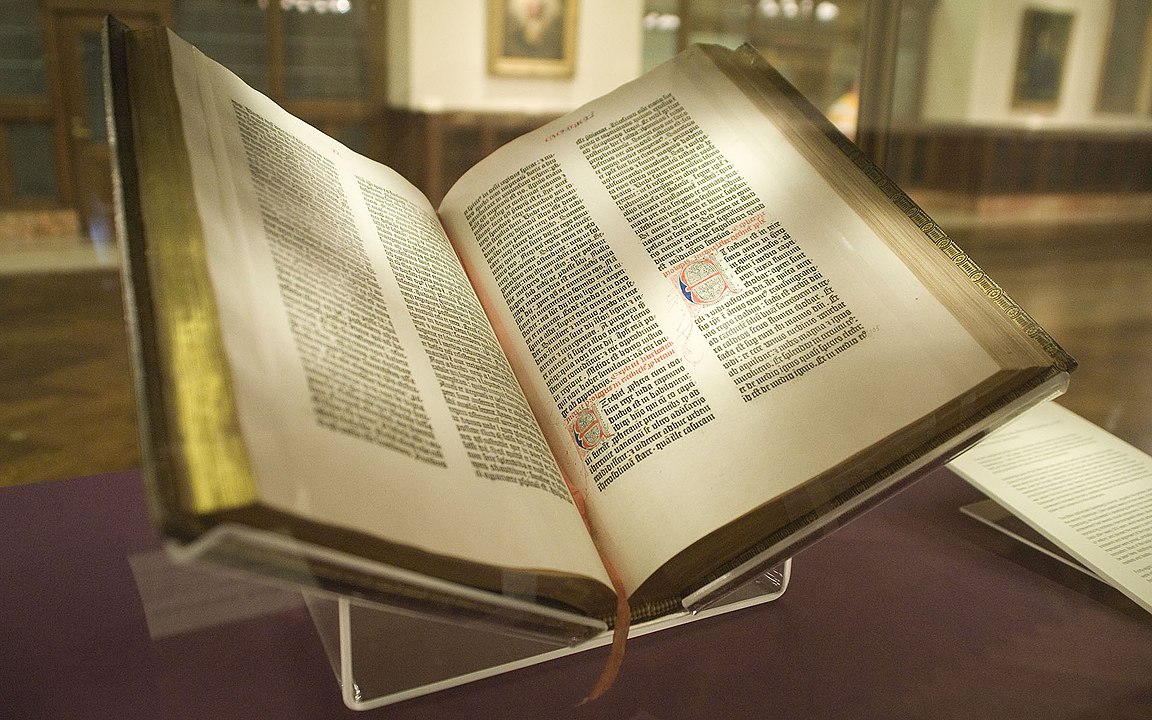

By NYC Wanderer (Kevin Eng) – originally posted to Flickr as Gutenberg Bible, CC BY-SA 2.0, https://commons.wikimedia.org/w/index.php?curid=9914015

For the collector of documents, manuscripts, letters, we know that paper making is an ancient practice. Before the industrialization of the paper production the most common fiber source was recycled fibers from used textiles, called rags. The rags were from hemp, linen, and cotton. It was not until the introduction of wood pulp in 1843 that paper production was not dependent on recycled materials from ragpickers. It was not realized at the time how unstable wood pulp paper is. We know documents made of 17th and 18th century paper will last longer than documents made of early 20th century paper.

History of Paper Making

Paper making itself is an ancient practice. The ancient Egyptians crafted papyrus as early as 4000 BCE. Papyrus is layering strips of reeds to form thick sheets and scrolls of writing materials. The first true paper originates from China in 105 CE. Han Dynasty court official Cai Lun boiled a mixture of bamboo, bark, rags, and other fibrous material to form a wet pulp which he shaped and dried to create a thin, lightweight sheet of bound fibers. Cheaper and more convenient than the woods and silks traditionally used for writing, Lun’s paper earned him fame and favor throughout the Chinese Empire and in the centuries that followed. His technique spread across the globe.

Regardless of its widespread popularity, paper remained an expensive luxury item. It is not until the 19th century that the cost of began to go down. Early mills relied on skilled artisan workers to craft the sheets by hand and shortages of raw materials like cotton and linen rags drove the prices up. Barry Read chief executive of the Paper Industry Technical Association has noted, ‘‘Commercial paper making didn’t begin until the invention of the steam-driven paper machine and the switch to wood pulp. The first paper machine in the UK was designed in 1806. It is the same fundamental design and process used today.”

Chemistry of Paper Making

At a chemical level, paper is made of cellulose fibers pressed and bound together by hydrogen bonds. It’s the crucial pulping step that accounts for paper’s unusual strength. The heat, water and fiber all attract microbes. Despite the complexity of the production process, the paper industry boasts impressive green credentials. There’s a real focus on sustainability and mills repurpose any waste or byproducts, using them to generate carbon neutral energy or provide feed stocks for other industries.

Collecting

So, the documents of the future might degrade even more quickly because they are designed to be “green.” Will recycled paper make every collector find new ways to save and preserve their future collections? That is a good question.

Read the entire article on paper production and the work to make the industry sustainable and paper recyclable.

Leave A Comment